Sensors that never stop monitoring

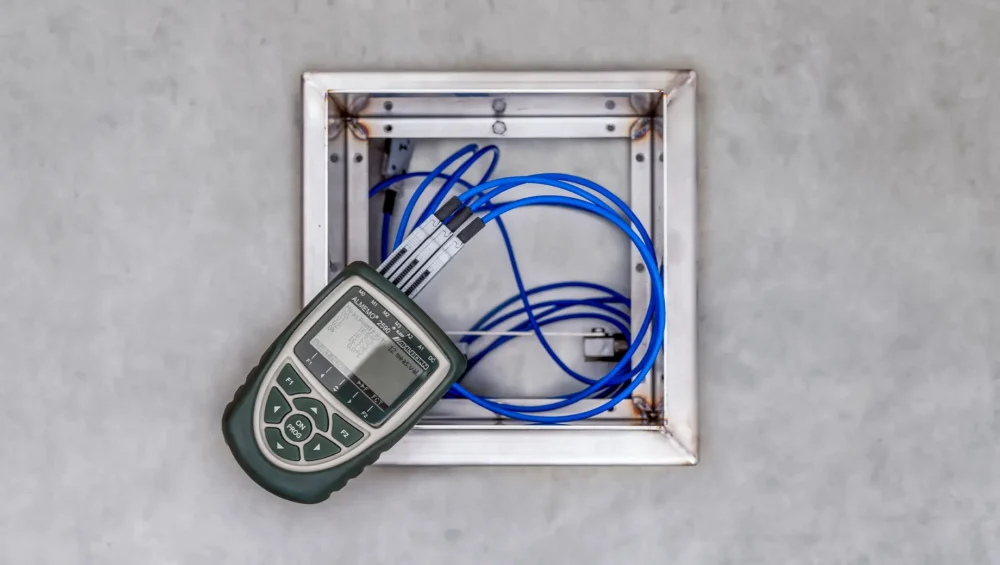

The tens of millions of square metres of logistics floor laid over the years have yielded us a wealth of information. Data we use to develop an intelligent concrete mix for every project that takes almost every parameter into account, from raw materials and aggregates to weather conditions while pouring and the load during use. And after you start using the floor, sensors in the concrete provide information 24/7, allowing us to monitor and guarantee the promised specifications.

Van Berlo Technology

01

Our technologies

Concrete Intelligence

The data-driven solution for prefab concrete

Conventional production processes have too many limitations to create a quality and highly sustainable concrete mix. Van Berlo steps into the future with Concrete Intelligence, a technology that enables us to calculate and control the entire production chain. A data-driven solution from raw material through to finished product and beyond.

“Since we measure and therefore have all the data, we can predict exactly how a concrete mix will behave.”

02

Mini Vibro

Mini Vibro

A high-quality and economical foundation system for every substrate

A logistics floor needs to be reliable, regardless of the surface it sits on and the processes that take place on it. The Mini Vibro system is a foundation technology developed by Van Berlo that can handle heavy floor loads on less load-bearing substrates. A high-quality and also very cost-efficient solution.

Guaranteed performance

The engineers at Van Berlo develop a design that is calculated down the smallest detail and tailored to your future floor load and the properties of the subsurface. To guarantee the desired performance, we keep all production in-house and the Mini Vibro piles are acoustically measured five days after production. Mini Vibro has been living up to its promise for clients including Kuehne Nagel, Wehkamp, WDP, LIDL and Vos Logistics. Besides the Netherlands, it is also used in Belgium and Germany.

The Mini Vibro Pile is included in the Dutch National Environmental Database.

03

Flex Foundation

Flex Foundation

Technology for customised construction in a shorter time

Loading pits and dock structures need to meet the toughest construction standards to seamlessly link your internal and external transport, taking into account all common truck types. Their construction and use face a number of practical challenges. Van Berlo Flex Foundation provides the solution for distribution centres and warehouses, optimising the logistics work for contractors, developers and users.

High quality in less time

Flex Foundation is a technology that delivers as many prefabricated components as possible. The result is a customised solution with a shorter construction time, benefiting both the contractor and developer. Because Flex Foundation is prefabricated, the weather doesn’t affect the quality and progress of the construction process. Most obstacles in the construction process are eliminated, so that a project is almost always completed in less time. Our team of specialists will be happy to tell you more about this in-house developed construction system.

Flex Foundation is ideal for

- Foundation structures

- Dock structures

- Loading pits

- Gutters and drains

- Solid hollow walls

Our engineers are always happy to tell you more about the prefab solutions for warehouses and distribution centres.

04

Greymatter

Greymatter

Crack-free floors with 50% lower CO₂ emissions

The concrete floor in large distribution and warehousing centres represents half of the building’s total CO₂ emissions. We can do better. Van Berlo’s Greymatter technology makes commercial floors significantly more sustainable, without compromising on quality and performance. By reinventing a classic building material, we are able to achieve the biggest CO₂ reduction in the market.

Avoid downtime

Especially across very large surfaces, shrinkage can cause cracking in logistics flooring that can lead to costly repairs and downtime. Van Berlo sees the floor as the foundation on which your logistics process has to run smoothly. You valuable robots and machinery can only perform effectively in a highly automated environment on a floor that is flat, smooth and stable.

What can we do for you?

Do you have a question or would you like more information? Our specialists are ready to help you. Please feel free to contact us.